Ackumen™ Closed Loop Management

Hot and chilled closed loops require proper water treatment or they risk corrosion and deposition. However, there is often a set-it-and-forget-it mentality so they are often overlooked until there is a problem. Monitoring usually consists of corrosion coupons and water meter which is cumbersome, time-consuming and reactive instead of proactive. Corrosion and bacteria issues can lead to leaks that can result in process shutdown, costly damage to your process equipment, and even worse, product contamination.

What if you could:

Be proactive when it comes to managing your closed loop

Increase process uptime or reduce process downtime

With Ackumen Closed Loop Management, you can.

Proactively monitor your closed loop, instead of reacting to system changes when it’s too late. We are elevating the importance of closed loops especially in process applications when unwanted downtime or replacement costs significantly impact your operation. Normally closed loops are overlooked, and a lot of times this is what causes the issues.

Leverage the expertise of the Insights Lab to monitor your system continuously, providing actionable recommendations and peace of mind that allows you to focus on other areas of your facility. They bring the expertise so you don’t have to.

Utilize traced chemistry to continuously monitor inhibitor levels. This ensures you have proper system protection at all times whether from unwanted water loss or system leaks.

Continuously monitor corrosion to ensure you are protecting your valuable assets and preventing unwanted downtime.

Monitor turbidity online, which provides insight into system upsets and process leaks.

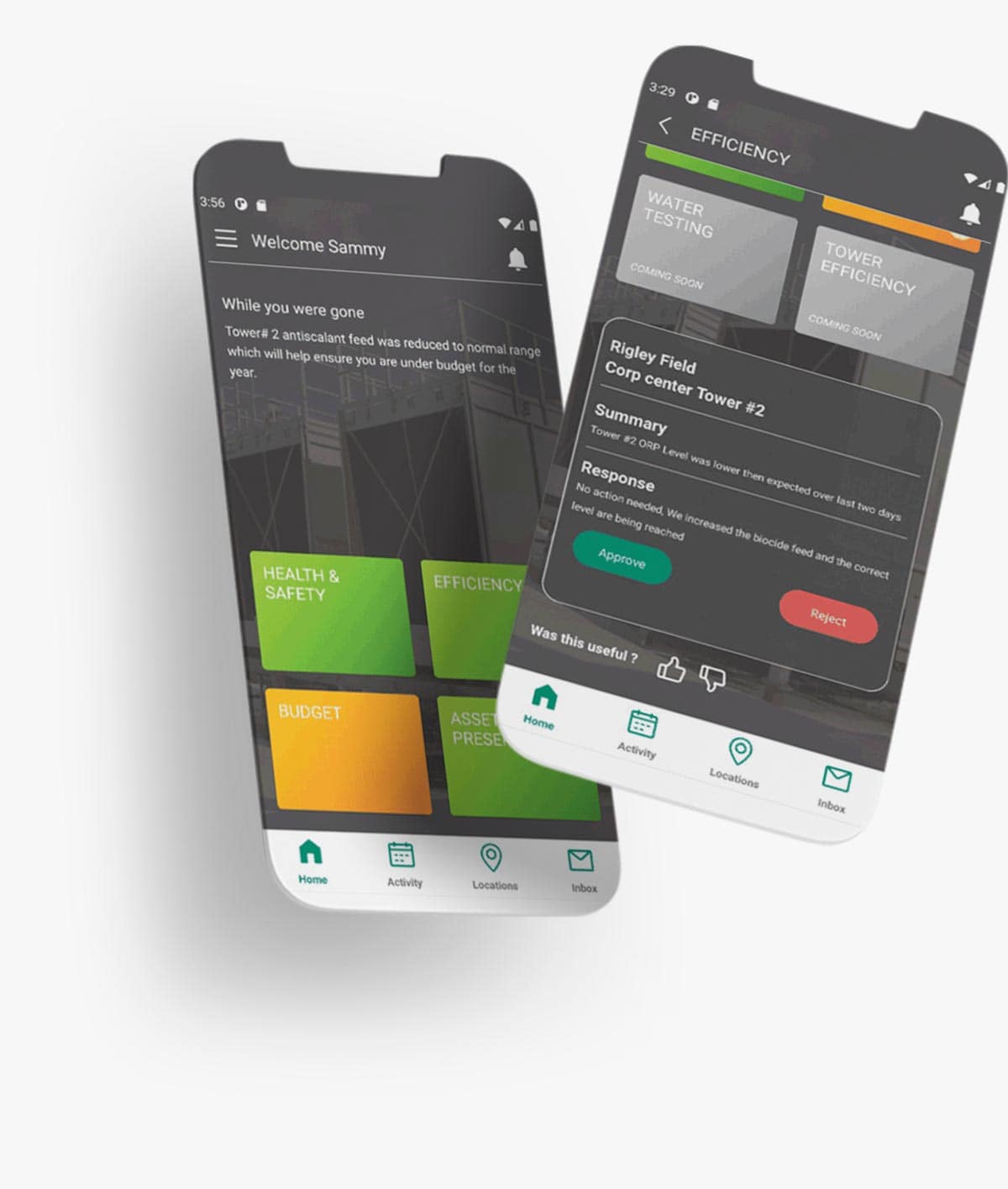

Get insights to help you succeed

The Ackumen digital solutions platform uses cloud-based data to deliver important insights right to your mobile device or desktop. You’ll get easy-to-read, actionable system graphics that show you how process indicators are behaving. You’ll also get alarms and notifications. And with just a glance, you’ll know whether an action is needed now or later.

Relax with support from the experts

The Insights Lab provides 24/7 monitoring by a team of data scientists and engineers. They deal with events as they happen. Assess every alarm. Eliminate false ones. And let you know if any action is recommended.

Manage chemistry better

SMART Inventory is our automatic inventory control system. It uses IoT sensors to monitor chemical supply in any container. You’ll get 24/7 inventory insights delivered directly to your mobile device. You’ll also get usage-based alerts, one-click ordering and more. Managing your chemistry has never been more efficient.

Have confidence in a safer work environment

When it comes to leak detection, we go the extra mile. Every panel on our skid contains a sensor. So if there’s a problem, such as an open valve, leaking chemicals, or a broken line, you’ll receive an alert that can help you prevent accidents.

Plus, through SMART Inventory and automatic reorders, you can minimize onsite chemical storage and still be confident you won’t run out of chemistry. With Ackumen, you also get alternative chemical delivery options that can help reduce the need to handle and store chemicals, and because no large containers are used, your employees are less at risk when it comes to switching out chemicals.

Be proactive, not reactive.

Ackumen Closed Loop Management provides automated monitoring and control of your closed loop systems, allowing you to operate your processes with higher efficiency and lower downtime without the added burden on your team.